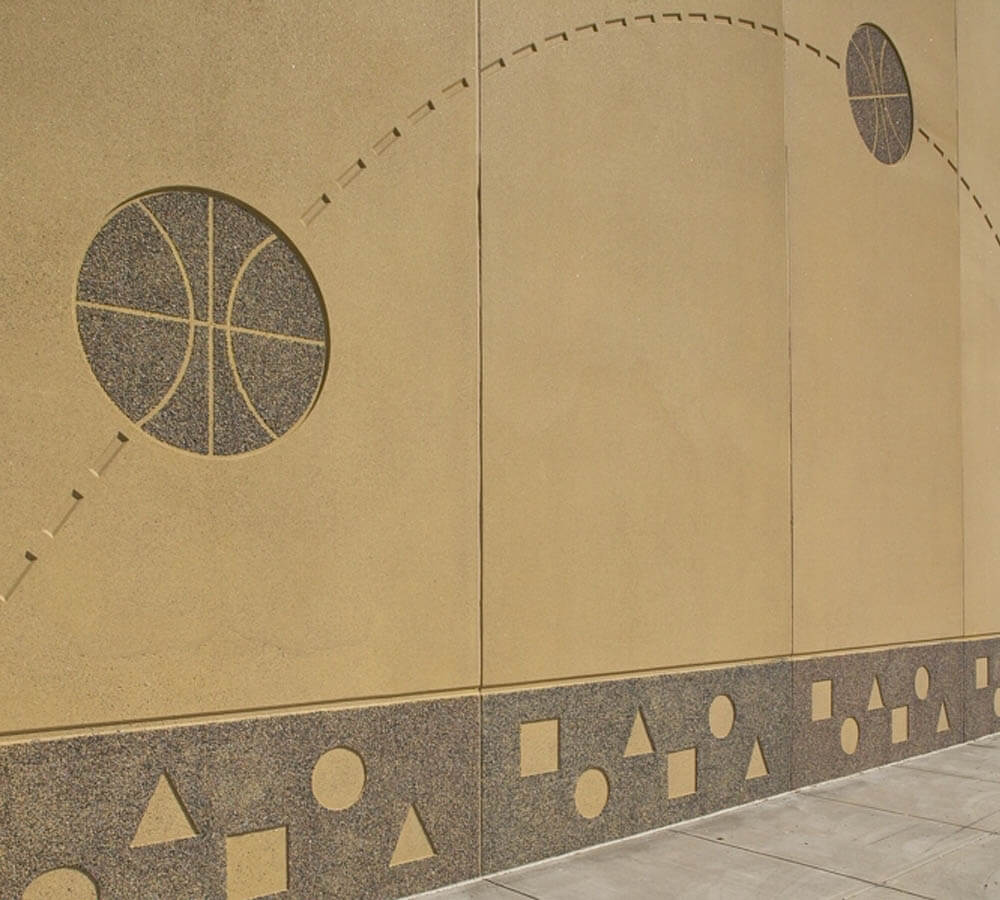

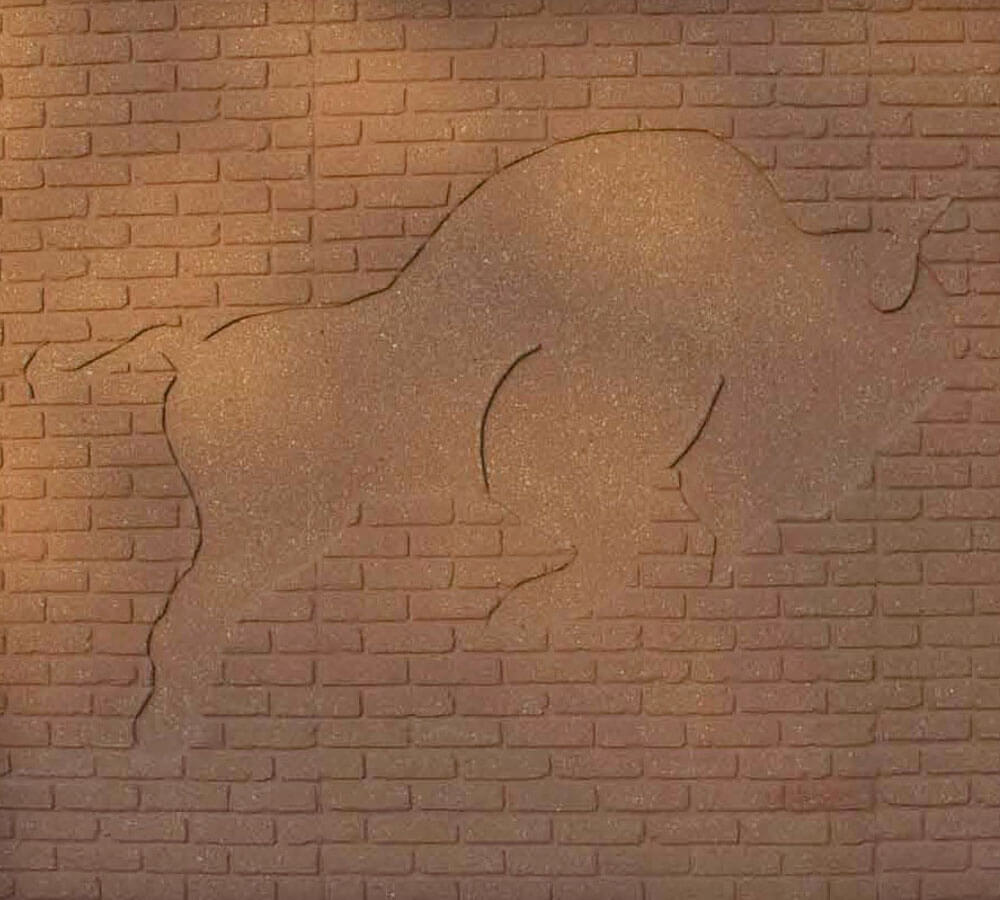

The use of precast concrete in public art applications is growing in popularity with incised lettering and emblems used to identify structures – company logos, school mascots, tag lines, etc. A wall with creative images reduces the visual scale of the panels and turns the wall into a work of art. These options not only add visual interest and visually reduce the building’s mass but they also can customize the building to add personality and personalization.

New techniques and technologies provide a wide array of design possibilities ranging from traditional building patterns such as masonry, wood board markings, and stone textures, geometric, rhythmic, fractured fins and fluted textures, as well as custom graphics including highly detailed three-dimensional graphics. Combine our other finishes together with formliners, and the possibilities are almost infinite. Architects are now able to push the envelope in their façade designs.

There are typically three different types of custom graphics that can be achieved with formliners, either produced by liner manufacturers or Wells Concrete:

- A two-dimensional pattern milled into or attached to a mold. Graphics could be letters, dates, and simple flat-planar designs.

- Multiple planes to produce a graphic that may have different types of textures, such as abrasive blast, bushhammered, or fractured fins.

- Three-dimensional, photo-realistic graphics achieved through computer numerical control (CNC) milling of the formliner (photo-engraved) or use of a special membrane with embedded retarder where the retarded surface is exposed (photographic).

Architectural precast concrete not only offers design freedom of architectural expression with visually interesting shapes that are functional in application, it also contributes to durability, sustainability, energy efficiency, and improved occupant comfort and safety. At the same time, the initial plasticity of concrete makes it responsive to the designer’s creativity.