PRECAST PRODUCTS

SlenderWall

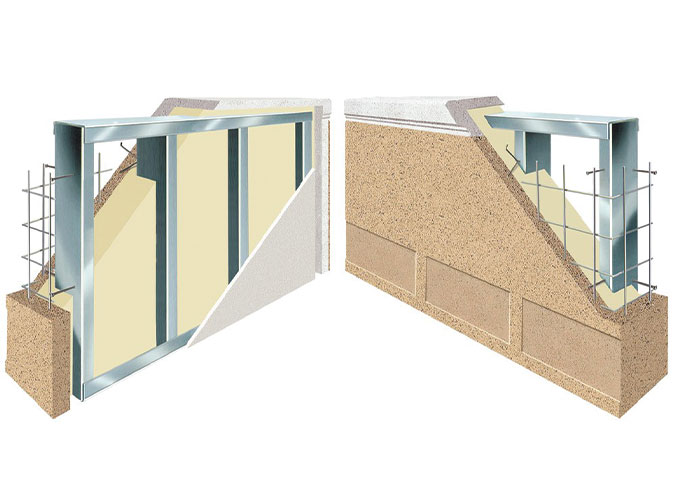

SlenderWall is a thermal and fire code-compliant, ASTM E119 fire-tested, architectural precast composite cladding system. It reduces structural costs and on-site trades with the only envelope system that combines proven technologies – architectural precast concrete, PVA fiber and welded-wire reinforcing, stainless-steel fasteners and ready-for-drywall heavy gauge galvanized steel studs – to create a single efficient solution for new construction or re-cladding.

It is designed to be lightweight (66% less than traditional architectural precast), reducing foundation and superstructure requirements, as well as shipping and installation costs. The exterior precast concrete cladding and integrated steel stud system are isolated from the structural stresses associated with: wind loading (tested to 226 mph), steel frame movement, expansion and contraction, and seismic shock.

The architectural concrete is connected to the steel-stud frame utilizing stainless-steel fasteners, creating a thermal air gap. The frame is then filled with factory-applied NFPA 285 fire-rated closed-cell foam insulation, creating a continuous insulation and air barrier that meets thermal requirements.

Architectural Precast Finishes

- PCI Quality Control Standards

- Same colors, textures, and finishes as traditional precast

- Welded-Wire Mesh and Fiber Mesh Reinforcement

- Returned finishes at edges, openings, and ends of panels

- Other finishes (metal panels, laminates, etc.) can be cast-in or preinstalled prior to shipping

- Multiple finish offerings reduces the need for other trade contractors on site.

Steel Frame Back-up

- Galvanized steel stud framing

- Optional preinstalled electrical boxes and conduits

- Drywall ready

Factory Installed Spray Foam

- Installed in factory controlled conditions

- Energy Code Compliant

- UL and NFPA 285 tested

- Continuous Insulation for applicable Climate Zones

- Insulation R-Value of 7.4 per inch

- Provides primary vapor barrier for exterior wall

- Improved consistency and Quality Control

- Fewer on-site trade contractors

- Panels are already insulated when they arrive on site

- Spray foam meets 2020 guidelines for blowing agent restrictions

Factory Installed Windows

- Installed and caulked in factory controlled conditions

- Greater control over quality of install

- Installation performed at ground level in controlled conditions

- Window testing performed in factory prior to arriving on site

- Factory installed windows allow for faster enclosure schedules

- Fewer on-site trade contractors

- Eliminates the need for material staging areas on site

- Panel openings shipped to the site weather tight allowing other trades to start sooner & eliminates temp enclosures

- Lower overall cost

Testing – Research & Development

Wells continues to invest time and resources in Research and Development to proactively assure our products meet and exceed the required testing standards necessary for today’s construction industry.

Final NFPA 285 testing reports have been completed; Wells SlenderWall and IES systems now have their own assembly listing in the UL catalog for Exterior Wall Systems: EWS0051. This is a test of a two story section of our light weight wall panels to verify that our system does not contribute to any vertical flame spread on the exterior of the building. The testing reports will be done on our actual systems so that judgment letters will not be needed.

In summary, SlenderWall is a unique precast concrete cladding system that combines the precast façade, insulation, windows, and an interior steel frame in one composite panel; all pre-assembled in our enclosed manufacturing facility. This results in a durable, high quality, lightweight, and low maintenance product that installs quickly and offers designers a wide range of color, texture and detail choices. This new, high-value precast solution reduces costs, improves schedules, and decreases the need for on-site trades.